The CMT 552-7 Diamond Dry Hole Saws are the professional's choice for precise, chip-free drilling in extremely hard materials like porcelain tile, glass, stone, and masonry—where conventional hole saws fail. Engineered with diamond grit edges for superior grip and 2–3x longer lifetime, these Italian-made saws feature a 30° initial drilling angle to prevent slippage, orbital motion for optimal cooling and chip evacuation, and compatibility with water as a cooling agent. Available in sizes from 3/16" (5mm) to 3-1/2" (89mm) with 5/8-11UNC thread—ideal for plumbers, electricians, and tile pros. Max 14,000 RPM; turn off hammer action for best results.

• Diamond grit edge technology – Exceptional grip & performance in extremely hard tile, stone & masonry

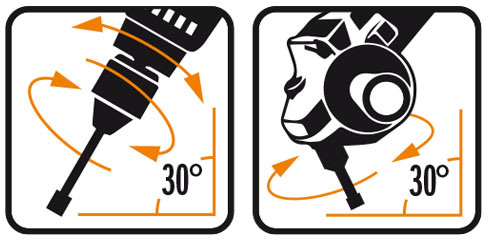

• 30° initial drilling angle – Prevents slippage for clean, accurate hole starts every time

• Orbital motion recommended – Better cooling & chip evacuation for longer tool life

• Water-compatible cooling – Optional for peak performance in demanding applications

• 5/8-11UNC thread – Standard fit for most drills; max 14,000 RPM

• Sizes available: 3/16"–3-1/2" (5–89mm) – Covers small plumbing/electrical to larger knockouts

• 2–3x superior lifetime – Outperforms conventional carbide hole saws in hard materials

• Made in Italy – CMT precision engineering for professional results without chipping

• FREE Shipping!

- 552-705 Ø 5mm (3/16")

- 552-706 Ø 6mm (1/4")

- 552-708 Ø 8mm (5/16")

- 552-712 Ø 12mm (1/2")

- 552-GUIDE

- 552-EX16 - Hexagonal adapter for electric drill

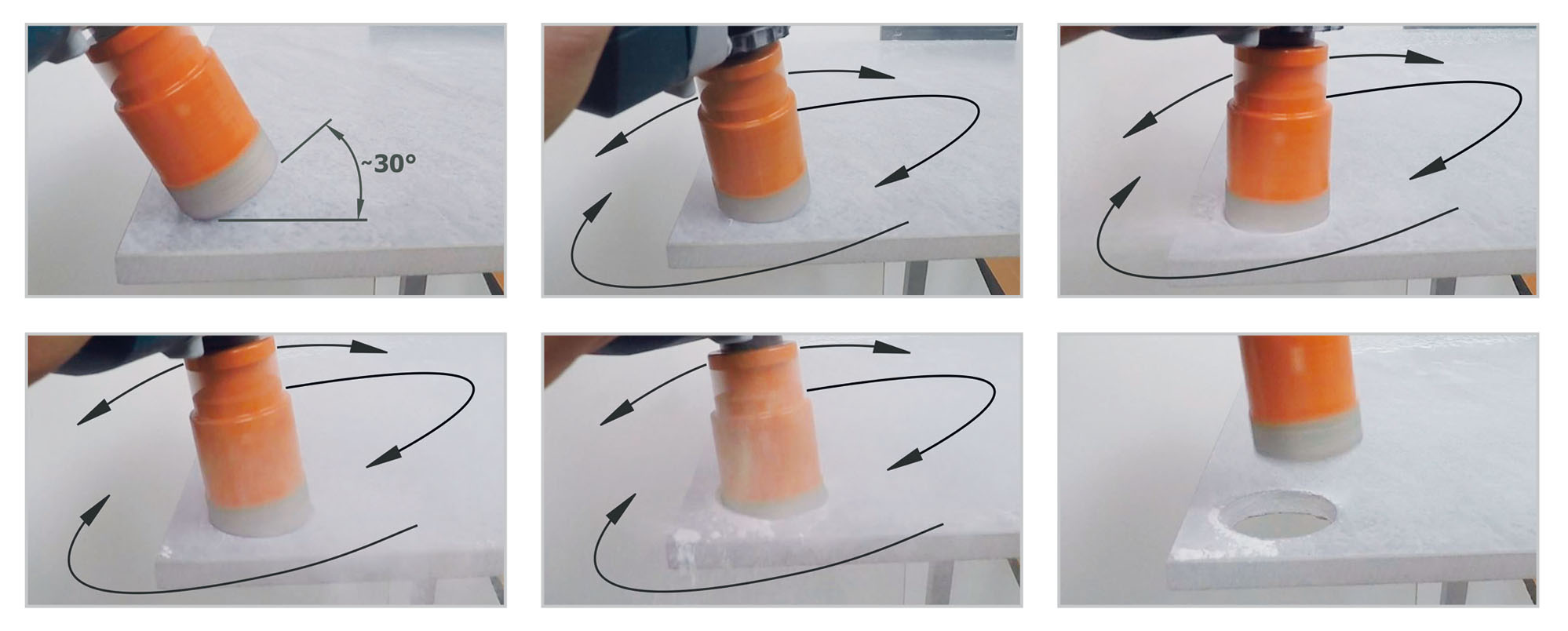

Turn on the drilling machine to start tool rotation. Begin drilling approximately at a 30° angle – this is the angle measured between the hole saw and the working surface. Cutting at an angle will prevent tool slippage, allow for perfect centering and increase cutting precision.

To gain improved stability through the drilling process, it is advised to rest the drilling machine on the working surface.

Continue the cut vertically, accompanying the tool in an orbital motion. This will favor better cooling and chip evacuation. (If you are using a guide, begin the cut vertically, then lift the guide and continue cutting in an orbital motion).

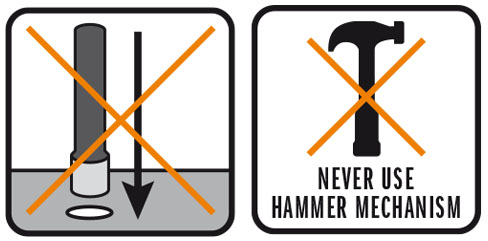

Continue the cut vertically, accompanying the tool in an orbital motion. This will favor better cooling and chip evacuation. (If you are using a guide, begin the cut vertically, then lift the guide and continue cutting in an orbital motion). Remember that the tool you are using is not a drill bit. This means that attempting to bore holes perfectly perpendicular to the work surface on a frequent basis will drastically reduce the life of your hole saw.

Remember that the tool you are using is not a drill bit. This means that attempting to bore holes perfectly perpendicular to the work surface on a frequent basis will drastically reduce the life of your hole saw.